Polyx®-Oil Tints

Colour and Protect In One

Transform and protect your wood surfaces with Osmo Polyx®-Oil Tints, a premium coloured hardwax-oil finish that delivers rich colour and lasting durability. Designed for hardwood floors, furniture, and interior woodwork, this innovative finish enhances the natural grain while providing superior water and wear resistance. Get your favourite finish, now in a tinted version.

Recommended for: Ideal for protecting all wooden floors, such as solid wood and plankwood flooring, blockstrip, OSB and cork floors, wood trim and sheet products, as well as for furniture.

Tinted Hardwax-Oil

Polyx®-Oil Tints is the coloured hardwax-oil version of our best-selling Polyx®-Oil Original. Discover the original version available in matte, satin and gloss clear finishes.

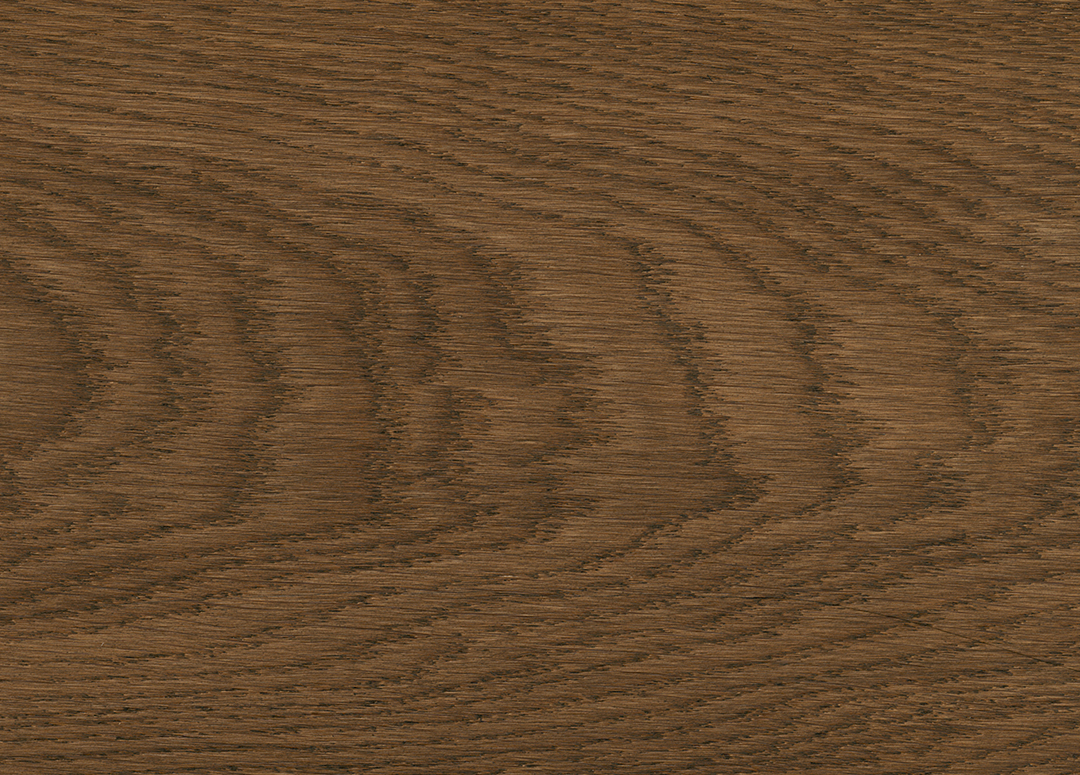

Polyx®-Oil Tint Colours

Note: The colour shades shown are a true likeness of the original, after application onto Oak. However, some variation may occur due to screen brightness and uploading processes. It is advisable to test colours on a small sample, as colour may appear differently on other wood species.

What to expect with Polyx®-Oil Tints

Bring out the natural beauty of wood with rich, subtle colour and a finish that lasts. Polyx®-Oil Tints combine colour and protection in one—resisting spills, scuffs, and everyday wear while keeping wood breathable and easy to refresh. Expect depth, durability, and a surface that looks beautiful for years with this coloured hardwax-oil finish.

Choosing the right application tool

Different species of wood require different amounts of product to achieve the highest durability and stain resistance. This is especially important for finishing high-traffic areas like flooring, stairs, countertops, and cutting boards.

Wood species and their recommended application amounts →

Before applying any Osmo finish, proper sanding is essential. For step-by-step guidance and expert tips on preparing flooring, furniture, and exterior wood, visit our Sanding Preparation page.

Stir the finish well prior to use.

- Using the Osmo Microfiber Roller, Osmo Floor Brush (for larger areas) or an Osmo Bristle Brush (for smaller areas), work product thinly and evenly in the direction of the grain. Brush out lap marks or stop marks.

- Mistakes can be corrected up to 30 minutes after the first application. Do not remove excess product, this will absorb into the wood surface over the drying period.

- Drying time approx. 12 – 24 hours (normal climatic conditions, 73°F / 50% rel. humidity). Lower temperatures and/or higher humidity can affect drying time. Ensure space is well ventilated.

- Apply second coat thinly and evenly, as before. Allow 12 – 24 hours drying time.

- A third coat is usually not required, however, highly absorbent wood or dry timbers may need a third coat.

Note: For high-quality finishes on items like tabletops, a smoother result can be achieved by lightly sanding the surface after the second coat has fully dried with a P320 or P400 grit sandpaper, and then buffing 1-2 coats with a cloth or white pad.

Third Coat: Usually a third coat is not required, however highly absorbent or dry timbers may appear to require a third coat.

Please consult OSMO technical support at 1-844-OSMOCAN prior to carrying out a third coat

Cure Period: Osmo Polyx-Oil(s) like all finishes have a cure period. We recommend allowing 2-3 weeks for the surface to fully cure and harden prior to damp-mopping or placing rugs/mats on the surface.

Before applying any Osmo finish, proper sanding is essential. For step-by-step guidance and expert tips on preparing flooring, furniture, and exterior wood, visit our Sanding Preparation page.

Not recommended for high-wear surfaces like flooring, floors, stairs, tabletops, countertops and cutting boards.

Stir the finish well prior to use.

- Work the product into the wood thinly and evenly in figure 8 or circular motions using a white pad. Be sure to thinly and evenly coat the surface and leave on the surface.

- With a clean white pad, buff the surface ensuring no swirl marks, rings, or wipe marks. Use a clean white pad to buff until product has been worked into the grain and excess removed. Do not wipe off with a cloth.

- Drying time approx. 12 – 24 hours (normal climatic conditions, 73°F / 50% rel. humidity). Lower temperatures and/or higher humidity can affect drying time. Ensure space is well ventilated.

- Apply 3-4 thin coats with non-abrasive white scotchbrite pads, thinly and evenly, as before. Allow 12 – 24 hours drying time.

NOTE: Depending upon the species of wood (ie. Walnut) it may not be possible to achieve full durability and stain resistance when applying with a pad. If high durability is required (ie. Floors and Tabletops) we suggest to apply the coating using the Brush or Roller technique.

Cure Period: Osmo Polyx-Oil(s) like all finishes have a cure period. We recommend allowing 2-3 weeks for the surface to fully cure and harden.

Different applicators will provide different results regarding colour and the number of coats needed. Choose the best application method or mix and match to achieve the recommended amount of finish for your chosen wood species.

Microfibre Roller = Applies 30g/m² per coat – fastest application. 2 coats recommended.

Flat Brush = Applies 20g/m² per coat – best for textured surfaces and colour. 2-3 coats recommended.

Oil Applicator Fleece = Applies 15g/m² per coat – user-friendly, small build, medium colour intensity. 3 coats recommended.

White Superpad = Applies 10g/m² per coat – minimalistic finish, lower product waste, can be buffed to high luster. Not recommended for high-wear surfaces.

Cloth = Applies 5g/m² per coat – minimalistic finish and creates subtle colours. Not recommended for high-wear surfaces.

Video resources to make your Osmo experience seamless

Browse our application and tip videos for insights and inspiration.

Watch & Learn

Short, practical videos that show you exactly how to prep, apply, and finish like a pro

Pro Tips Step-By-Step

Choose the video based on your product, application tool, and project type

Choose Your Language

Videos available in English or French, so you can watch in your preferred language

Why Choose Osmo?

With over 140 years of wood expertise, Osmo is trusted in more than 90 countries worldwide for finishes that combine natural beauty with lasting durability. Made in Germany from renewable plant oils and waxes, our products penetrate deep into the wood to protect from within—enhancing grain, colour, and texture while keeping surfaces safe, strong, and easy to maintain.