Wood Wax Finish

THE PERFECT ALL-ROUNDER

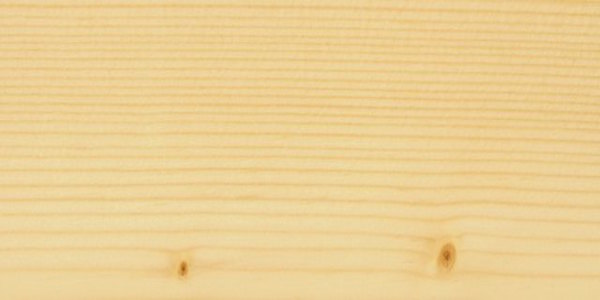

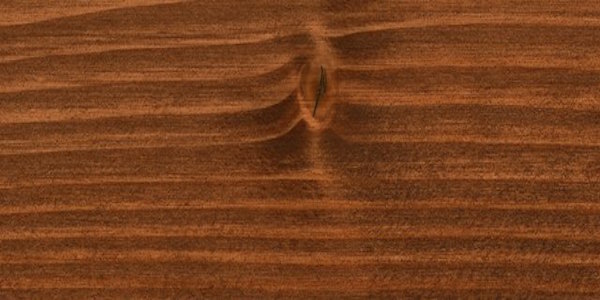

Osmo Wood Wax Finish is a satin-matte wood finish that combines the best of oils and waxes in a single product. It enhances and protects wood surfaces, offering exceptional durability while remaining water- and dirt-resistant. Easy to apply, it requires no primer or sanding between coats, saving both time and money. Resistant to liquid spills, and once dry, it is safe for humans, animals, and plants.

- Versatile interior use: Suitable for floors, furniture, and all interior woodwork

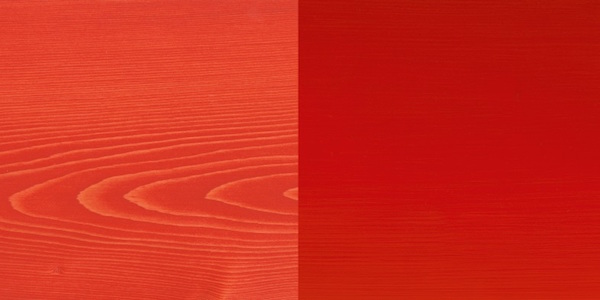

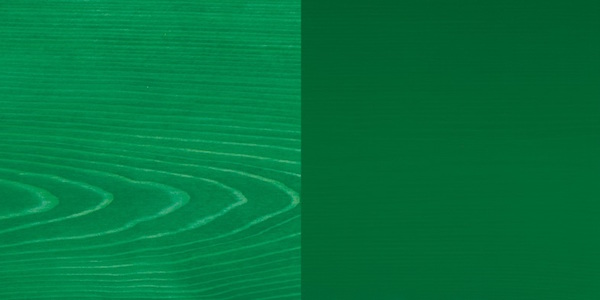

- Customizable appearance: Wood grain is visible with transparent tones, or opaque with intensive tones

- Based on renewable materials: Soybean, sunflower, thistle oil, and carnauba and candelilla wax

- Extremely durable and hard-wearing: Will not crack, flake or peel

- Water-resistant: Suitable for kitchens, bathrooms, and other rooms exposed to high humidity

- Spot-repairable and easy to refresh: Can be maintained without sanding

- Resistant to spills: Protects against wine, beer, cola, coffee, tea, fruit juice, milk, and water (DIN 68861-1A)

- Safe for humans, animals, and plants: Certified child-safe for toys (EN 71.3)

- Made in Germany: Meets strict German and European quality standards

- Easy application: Can be applied with a brush, roller, buffing pad, or cloth

SPECIFICATIONS

Approx. Coverage

258-517 ft²/L (24-48m²/L) per coat

Number of Coats

1 coat = Transparent; 2 coats = Intensive

Application Temp.

+5°C to 35°C

Approx. Dry Time

12 hrs.

Sizes

5mL, 125mL, 375mL, 750mL, 2.5L

TRANSPARENT COLOUR TONES

INTENSIVE COLOUR TONES