Decking Oil

MEETING THE DEMANDS OF CANADIAN DECKING

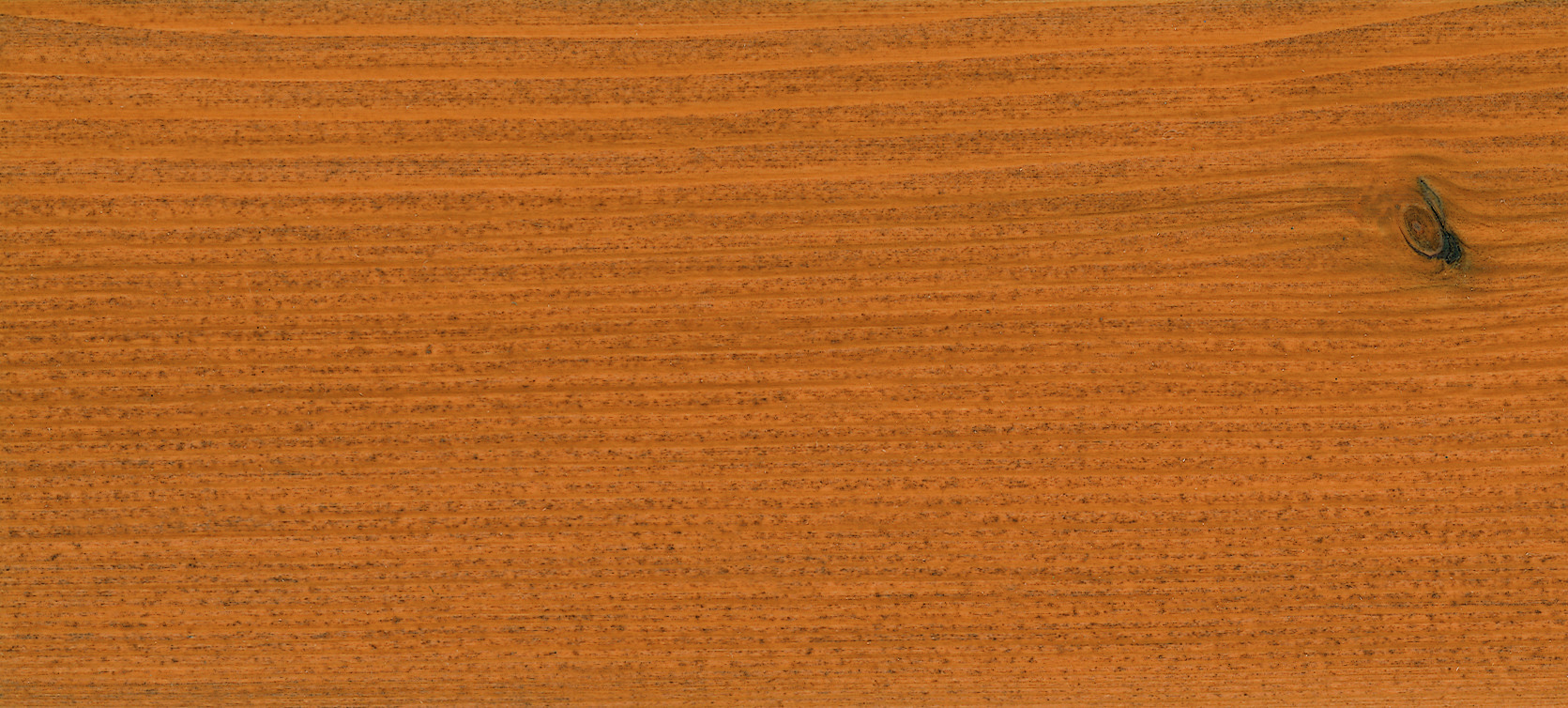

Water-repellent, extremely weather and UV resistant. Easy to apply and renew, no sanding or primer necessary. All Osmo finishes are microporous, so the wood retains its ability to breathe, preventing any peeling, cracking, flaking or blistering.

- Effectively colours pressure treated and untreated woods

- Natural wood character and grain remains visible

- UV-Resistant (except Teak 1277)

- Microporous finish that will not crack, peel or flake

- Safe for animals and plants once dry – naturally!

- Very water and dirt resistant – water beads on surface

- Reduces wood swelling and shrinkage

- No sanding necessary for future applications

- German quality = Easy application with professional excellent results

SPECIFICATIONS

Approx. Coverage

24m²/L (258ft2/L) with one coat

Number of Coats

2 coats

Application Temp.

+5°C to 35°C

Approx. Dry Time

12hrs

Sizes

0.75L, 2.5L