Meet the Maker: Paul Beeman, Beeman Woodworks

Specializing in modern case pieces with a handcrafted twist, Beeman Woodworks blends traditional joinery with contemporary design and technology. Drawing inspiration from Shaker furniture, classic woodworking texts, and hands-on study of iconic makers like Nakashima and Esherick, his work is grounded in deep respect for craft history—while still letting a bit of fun shine through.

From crawling under antique tables to exploring community-based learning and teaching at a local college, his approach is as hands-on as it gets. His ash credenza—a standout piece born from both technical challenge and personal growth—reflects this philosophy: craftsmanship shaped by experience, problem-solving, and genuine grit.

Now expanding his shop and fully committed to his own woodworking practice, Beeman is passionate about helping others break into the field, whether through community college, maker spaces, or the generosity of the woodworking community itself.

“It takes a genuine fight to produce one well designed object of relative permanent value.“

– George Nakashima

What do you specialize in?

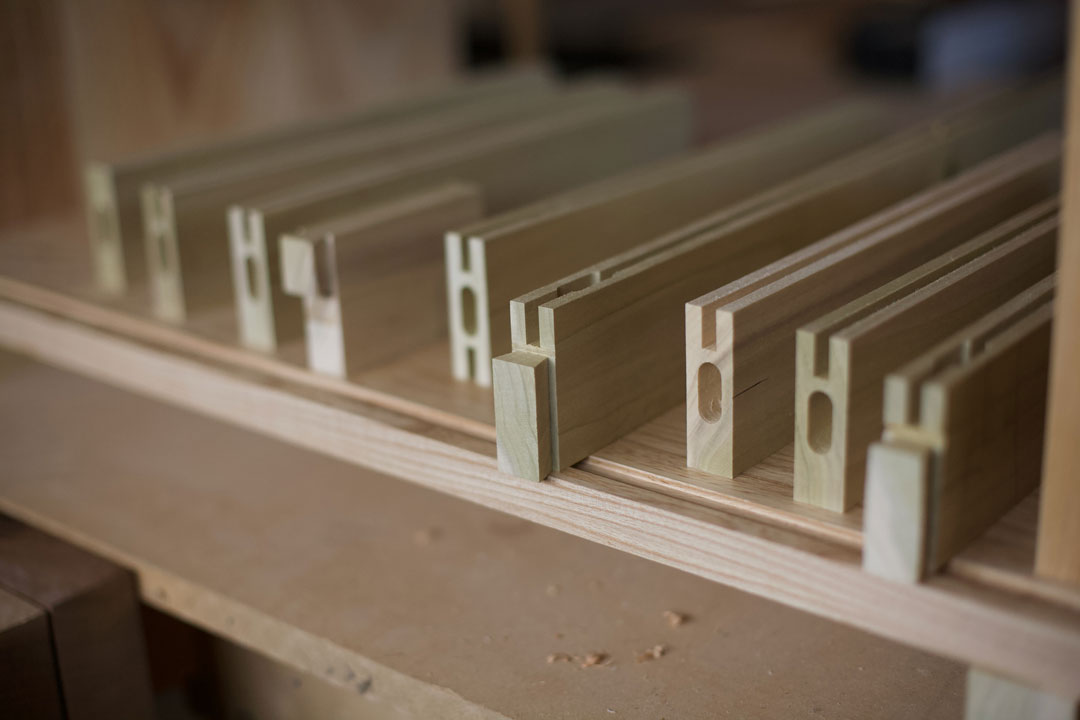

I would say that I specialize in case pieces that are informed by the modern craft movement. I try to allow a bit of fun to show through in every piece, along with facets from my hand tools, and while the designs are modern, the construction is a mix of traditional hand tooling and current technology.

As a woodworker, where do you get your inspiration from?

I have a lot of books, especially on shaker furniture. I employ a lot of joinery techniques and design proportions that are ripped straight from those books and then given some small modern twist to allow my own voice to come through a bit. I love everything that is published by Lost Art Press. I think most design is extremely incremental to what is already out there so as long as I can add a design element or two to the conversation I am usually happy.

I think seeing pieces in person is important, not only because it is inspiring, but it also cuts through so much misinformation. I used to live in New Jersey and I was lucky enough to see the Nakashima and Esherick studios in person. It blew my mind how many screws were employed in their furniture and it was very comforting to see that human, production-minded side of things. I also go to a lot of antique stores and crawl around under tables, open drawers, take pictures, etc. That is a great way to get inspiration and figure out production tricks that are/were actually used.

I also follow a lot of other furniture makers on social media. There are so many good makers out there right now that inspire me. I am really impressed with what is going on at a lot of the craft schools in America and everyone teaching at them. I spent a week at the Woodworking School at Pinecroft recently and spending time with other makers and seeing what was going on at the school was an incredible experience.

We’ve asked you to share some of your favourite pieces, can you tell us what makes them special to you?

The big ash credenza was a real battle. I built it in my one car garage and so it sort of dominated my life for several months, I didn’t really have space for anything else. It was also the first piece I built after moving to Albuquerque and wood really behaves differently in the high desert than it does on the east coast, so there were all sorts of “fun” issues that I had to get through. On top of that, I just packed a ton of new techniques into it – lumbercore, shop sawn veneers, L-tenons, a variety of traditional construction techniques, etc so there was a ton of head scratching and powering through mistakes.

George Nakashima said “it takes a genuine fight to produce one well designed object of relative permanent value” and that is one of my favorite quotes about craft. This piece feels like it is definitely something that will outlast me which is a great feeling.

I built it for some close friends up in Portland and was able to deliver it to them and see it in their space – which is a beautiful home – and it felt like it belonged amongst all the other beautiful objects, which was a huge confidence boost.

What are you the most excited about this year?

I am really excited that I am expanding my shop. I have worked as a woodworker in other people’s shops on and off for the last decade and finally decided this past year to go full time for myself which was a bold move as I am currently working out of a one car garage. I am in the process of building a shop that will be large enough to actually run a small business out of. I have also started teaching out of our local community college which has been really fun and I am looking forward to developing more classes.

Do you have any advice for someone looking to enter your field?

There are a bunch of different ways to get into woodworking. Obviously, one of the biggest barriers to getting into woodworking has been the cost, but you can definitely get around that. Community colleges are great resources for woodworking programs. In New Mexico, Santa Fe Community College has a great program. The community college maker space I work out of in Albuquerque, called Fuse, has tons of scholarships to take classes. Fuse has top-class metal and woodworking tools, and is very affordable. There is a really cool non-profit called the Chairmakers Toolbox that offers scholarship classes all over the country for aspiring chairmakers from underrepresented groups.

Join your local woodworking and woodturning guilds. They are great resources for learning and community building and are very affordable. There are people that are eager to pass on their skills and learning in a hands-on way is infinitely better than online. You will also have access to discounted tools from other members – that is how I got all my turning tools for pennies on the dollar. Lastly, if you engage in the craft scene locally it can lead to jobs either through commissions or working in a shop.

Don’t be afraid to reach out to people online and ask questions. Personally I have had nothing but good interactions with other woodworkers and met some really good people by just reaching out, complementing work, etc. I am always game to share tips and tricks!

What would you like to ask our audience?

I am always curious as to what tools woodworkers can’t live without. I know we have all bought unnecessary stuff, but what is the one tool you would have bought sooner in your career and how has it changed your practice is a question I would be interested in.

*Head to instagram and answer in the comments!

Where can people find you?

The internet! I am really good at putting my foot in my mouth…

@beemanwoodworks on Instagram

What is your favourite Osmo product and why?

Polyx®–Oil Tints 3051 Raw Matte is such a good finish. I love ash and wanted a finish that would, as closely as possible, maintain its natural tone. I saw that Sam Whyman @whymanfurniture used this on his work so I picked some up and it has been my go-to finish for ash ever since.

Polyx®–OilHigh Solid is a high quality natural oil and wax based Hardwax-Oil wood finish. Polyx-Oil’s clear coat finish was developed for hardwood floors, furniture and other interior woodwork. The product can be easily applied with a cloth, brush, roller or single disc floor buffer. This diverse hardwax oil is suitable for kitchens, bathrooms, and other rooms exposed to high humidity. Safe for kids and pets, Polyx-oil is the ultimate wood finish for your next DIY project or home renovation.

View more from Paul Beeman in the gallery below:

For more Osmo Maker Features, projects, reels, and inspiration, visit our Instagram.

ⓒ All images used in this blog post are copyrighted and provided with permission. Unauthorized use of these images without prior written authorization is strictly prohibited.