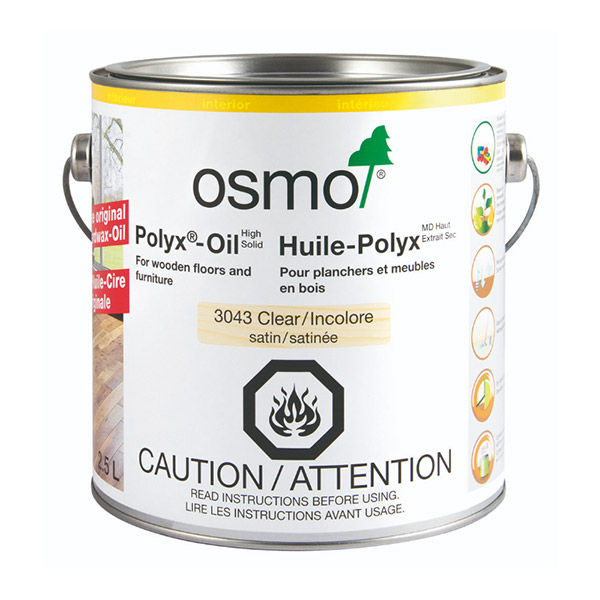

Polyx®–OilHigh Solid

THE ORIGINAL HARDWAX-OIL SINCE 1997

High quality natural oil and wax based Hardwax-Oil wood finish. Clear coat finish developed for hardwood floors, furniture and other interior woodwork. It can be easily applied with a cloth, brush, roller or single disc floor buffer.

- Based on renewable raw materials – soybean, sunflower, thistle oil, and carnauba and candelilla wax

- High solid content – offers 2-3x the coverage of conventional wood finishes

- Extremely durable and hard-wearing – will not crack, flake or peel

- Water resistant – suitable for kitchens, bathrooms, and other rooms exposed to high humidity

- Can be spot-repaired and refreshed without sanding

- Resistant to wine, beer, cola, coffee, tea, fruit juice, milk and water according to DIN 68861-1A

- Safe for humans, animals and plants and is suitable for children’s toys as per EN 71.3

- Made in Germany – Conforms to strict German and European norms

- Easily applied with a brush, roller, buffing pad, or cloth

SPECIFICATIONS

Approx. Coverage

258ft²/L (24m²/L) / per coat

Number of Coats

2 coats

Application Temp.

+5°C to 35°C

Approx. Dry Time

8-10hrs.

Sizes

5mL, 0.125L, 0.750L, 2.5L, 10L